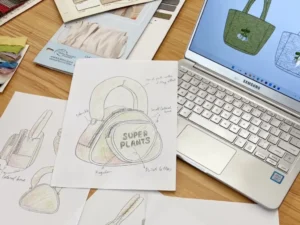

When you’re looking to bring your own bag designs to life, navigating the manufacturing process can be complex. Here’s an essential guide to ensure you’re well-informed and prepared:

1. Protect Your Design

It’s crucial to secure patents or trademarks for your designs. This step protects your creations and prevents potential intellectual property disputes.

2. Small Orders

For small batches around 20 units, consider partnering with smaller workshops, often run by couples. They usually offer more affordable labor costs, significantly reducing your production expenses.

3. Larger Orders

For orders exceeding 50 units, the base manufacturing cost per item can be around $130, depending on the complexity. Note, this cost does not cover materials like leather or hardware. The larger your order, the lower the cost per unit, explaining why factories often have minimum order quantities of 100 or 200 units.

Understanding the Manufacturing Process

- Material Selection: Decide on external and internal materials, accessories (sponges, non-woven fabrics, edging strips, etc.), and hardware. Special processing techniques for materials, such as printing or embossing, should also be considered.

- Mold Creation: Just like a puzzle, a bag is assembled from various parts. Molds or patterns are essential for cutting these pieces accurately.

- Leather Thinning and Edge Painting: Modern machines have made leather thinning easier, though it was traditionally done by hand. Thinning is crucial for parts that will be punched or sewn. Edge painting finishes the edges with a protective layer, a labor-intensive step.

- Stitching: This encompasses both machine and hand sewing. Some parts of the bag can only be stitched manually, adding to the craftsmanship.

- Final Inspection: Includes trimming threads, burning off frays, attaching tags, and packaging.

Quality Over Price

When choosing a manufacturer, don’t be swayed solely by cost. The quality of the output is directly proportional to what you invest. Inspect the manufacturer’s real, unedited product images and existing inventory to gauge their quality standards.

This guide aims to equip you with the foundational knowledge to navigate the bag manufacturing process confidently, from design protection to understanding the intricacies of production. Remember, a well-informed designer makes for a successful product launch.