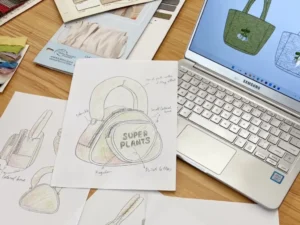

Ever wondered about the process behind customizing your own bags? Let’s break it down today, simplifying each step from concept to creation.

- Concept Submission: The journey begins with you providing a sample or a design concept to the factory’s design team.

- Design Confirmation: Once the basic design is greenlit, we dive into the details – confirming the bag’s structure, material combinations, and craftsmanship nuances.

- Pattern Drafting: Your design intentions and specifications are then handed over to our skilled pattern makers. They craft a paper pattern to check if the structure’s proportions are on point and whether the envisioned construction techniques are feasible.

- Prototype Adjustments: After the initial prototype is created, adjustments to the paper pattern may be needed. This refined pattern is then passed to the cutting master, who precisely cuts the materials as required.

- Assembly Begins: With materials ready, our sewing masters take over, stitching together your vision based on the design drafts and annotated patterns.

- Quality Check: Once the sample is complete, it’s back to the pattern maker to ensure the dimensions align with the original paper pattern, checking for any discrepancies within an acceptable margin of error.

- Final Touches: The last step involves meticulous packaging before the prototype is shipped out for your approval.

Through these seven steps, your custom bag takes shape, ensuring that what started as a mere concept becomes a tangible reality, ready for your feedback.